It's good to plan, but often the plan changes when you get to the real thing.

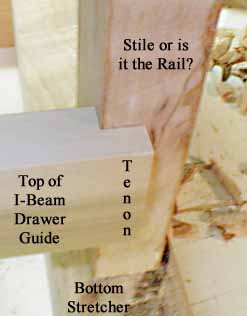

After doing the scaled drawings I found some 3/4 x 5 1/2" poplar and went the simple route. Ripped two strips 1 13/16" wide for the top and the bottom of the I-beam so they'd be the same width as the stiles (or are they the rails?) which have already been made and installed, That left - 1 1/2"! With a smidge less than 3/8" dados, that left a smidge over 3/4" inches between the insides of the top and bottom parts of the I-beam. Perfect for the 3/4" tall by 1/2" thick drawer guides on the sides of the drawers. Coincidence - or fate? Another "if you're doing what you're supposed to be doing things just work out".

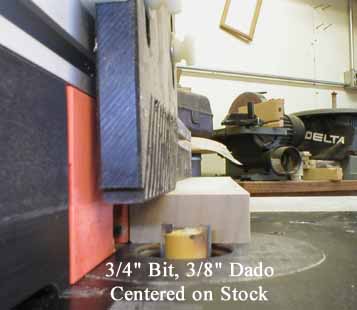

To route the dados I centered the stock on the nominal 3/4" bit (they're more often than not less than 3/4" diameter). this is easy on the JoinTech which self centers the bit knowing the bit diameter and the stock width - not theoreticl but actual. No measuring required. Very slick capability. I set up the feather board to hold the stock down on the bit, set the depth to just under 3/8" and made two passes, turning the stock around so the dado would actually be centered on the stock and actually be 3/4" wide.

Without changing the bit height I started creeping up on a tenon length that would leave space between the end tenons that fit nice and tight between the front and rear stiles. Take a little off each end, test the fit and take a little more until the tight fit has been arrived at.

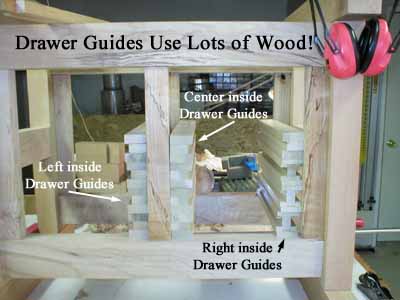

It's amazing how much wood you need when making solid wood furniture. Each drawer guide uses a 16" length of "1 x 6". There are twelve drawer guides so that's 16 lineal feet of "1x6". Granted, these guides are pretty beefy but the drawers will hold tools and they can weigh a lot more than a kitchen drawer of flatware or cooking utensils.

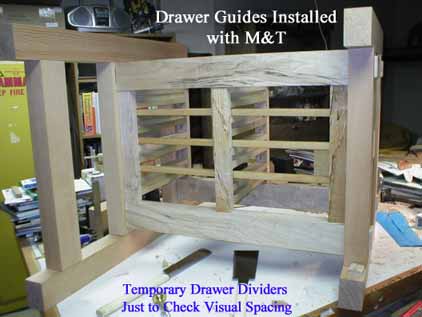

Forty eight mortises and tenons later, yet another disassembly and re-assembly, and the twelve drawer guides are in place

Now all I have to work out is the best way to notch the stiles to accomodate the male part of the guides which will be attached to the sides of the drawers. Want to make sure the notches are nice and crisp - no split out or tear out. Can rough out the bulk of the waste with a router and pare "to the line" or creep up on the line with the router taking very very light passes, or use a dozuki saw and chisel out the waste or ...