You've made the tool for cutting fine lines for inlaying. You've got a groove cut for the inlay. Now you need the inlay material. You've resawn or ripped some 1/4 inch thick strips and now you need to get rid of saw marks and get the two faces smooth and parallel AND the thickness of your cabinet scraper line cutting tool.

Well first you want to get rid of saw marks and make the two faces parallel - using your planer.

Two tricks to minimize snipe Michael Fortune demonstrated . First, bend the stock as you feed it. And lift the stock as it comes out.

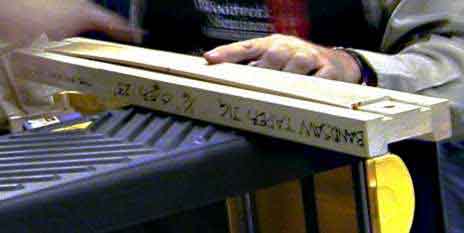

Here's his jig for safely machine planing thin stuff you'll need. Note the stops at each end.

The stock is cut a little long to allow a slight bow in the material. The planers infeed and outfeed rollers will press the stock down while planing.

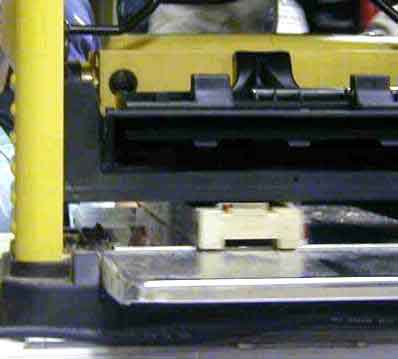

Here's the jig in use

Here's the jig exiting on the outfeed side. Note the bow in the planed stock. (sorry the image is a little blurred)

OK, so now the stock is close to the thickness you need. How do you fine tune the thickness? The planer is just too coarse a tool to use when you get this close to what you need.

On to the next tool you'll need - one you can make, again using a cabinet scraper.