OOPS!

(got your attention?)

This is my OOPS pages). Everyone makes mistakes but most woodworking sites never mention the screw ups and what caused them. This site is different. What follows will not only remind me not to repeat past mistakes but to explain what went wrong and what to do to avoid repeating them

Let's start with Norm's favorite - "And always remember to wear these (taps the frame of his safety glasses), safety glasses.

We all use power tools and hand tools that can seriously injure us and most of us are very aware of the importance of using tools, tailed or neander tools, safely. That, as Martha would say "is a good thing". BUT - we're less aware of the things that have the potential to cause us grief. Things on the floor that shouldn't be there can stub a toe or trip you at the most inopportune time. A sharp corner on your bench can do a number on your hip or stomach if you bump into it. A tall board, leaned "temporarily" at a less than stabile angle can nail you in the head or shoulder. While holding a mortising chisel too close to a deepening mortise you can be so focused on either the head of the chisel you're about to strike forcefully with a mallet or the cutting end that you fail to notice that you're about to pinch the your finger between the chisel and the edge of the mortise you're cutting.

But it's easy to forget that the nice staight board we milled up has sharp corners that can get you. Hold a nice newly milled board up and let it slip from your grip for just a second. That nice square edge can, and often will, cut you. Sharp edges and corners can get you, be they metal or wood.

And it's in those moments of minor triumphs that you get careless or, in my case, stupid. I'd just tightly fit a tenon into its mortise and had just patted myself on the back when I did something careless and I'm sure you will agree, stupid. The joint was tight, too tight. Tugging to get the tenoned piece free I got my face in the way of its exit path. Caught the corner of the upper tenon almost right between the eyes.

(see photo at the top of the page)

BTW - you can do something similar with a stuck mortising chisel, though it will likely catch you on the chin rather than between the eyes. Don't ask me how I know this (aka DAMHIKT for short). I can tell you that catching one "on the button" can make you see stars.

OK - now on to "cutting on the wrong side of the line"

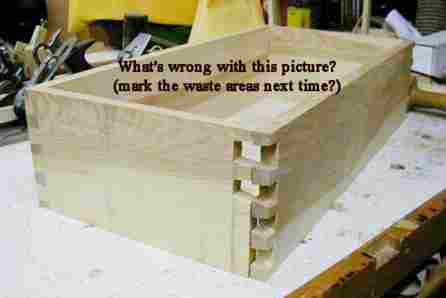

At some point, you're going to learn to make handcut through dovetails. It's not really that complicated or difficult but it does involve a bit of layout and concentration along with some sawing and chiseling techniques. And it's so easy to concentrate on getting the chisel on the pencil line or in the scribed line and angled properly AND FORGET WHICH SIDE OF THE LINE IS THE WASTE SIDE. You finish hogging out "the waste" and try a test fit. That's when you find out why you should ALWAYS MARK THE WASTE SIDE. (If you look closely at the picture below you will note that I'm a real slow learner. Did the other side nicely and perhaps got over confident. Dumb, really dumb)

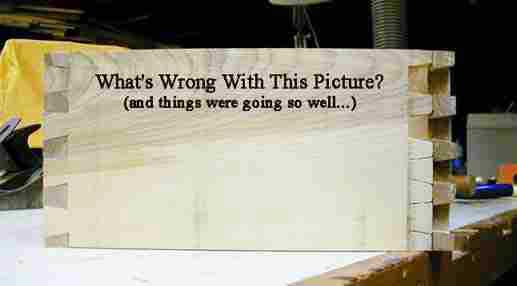

Here's another view - dumb huh?

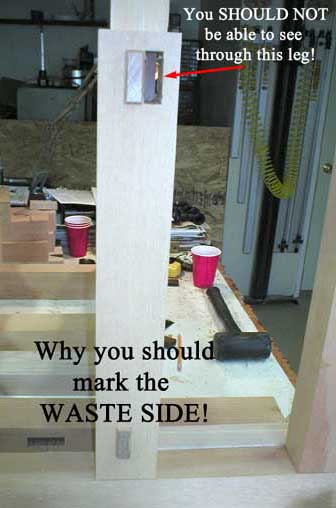

Here's another example of why you should mark the waste side. Again, concentrating on aligning a mortising chisel to the layout line I failed to notice which side of the line I was on.

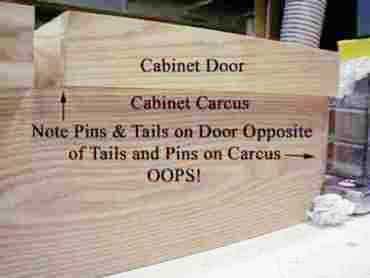

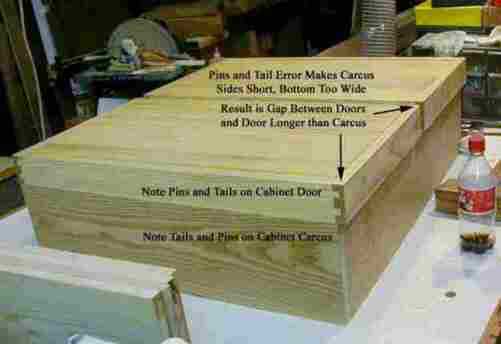

And here's a more subtle one. This one's from a wall hanging tool cabinet The cabinet is 7 1/2" deep and the doors are 2 1/2" deep. The "plan" was to do half blind dovetails, with the "blind" face visible and the joinery not visible unless you looked under the cabinet or at it's top. Of course, there's a structural problem with that idea since it would not be left/right forces trying to pull the sides apart that the cabinet would have to deal with. Rather, it was good old gravity and heavy tools that would be trying to push the bottom of the cabinet out. By putting the tails on the top and bottom boards and pins on the side pieces I'd lost all of the mechanical value of the dovetail joint, half blind or through, it was a dumb idea. But that wasn't "the oops" on this one.

I'd been very careful to cut the sides of the cabinets and the sides of the doors exactly the same length The top and bottom of the cabinet were cut to exactly the same length. The tops and bottoms of the doors were cut to half the width of the base and top of the cabinet (two doors, half the opening width)

I cut the pins and the half blind tails on a Jointech Cabinet Maker System on a router table ( though the screw up could probably be just as easy to do with a dovetail jig). This required both bit height setting, finding the center of each board and setting up a template for the 1/2" bit I was using. And there's usually a little trial and error tests done before getting down to cutting pins and tails in the real parts "in production mode". In that process, it's very easy to be so focused on getting a nice tight fit and performing the operations in the correct order with the stock oriented the correct way, that you forget what your real intent is.

With half blinds, with tails top and bottom in this case, or front and back in the case of a drawer, and pins on the sides, the width is the critical dimension and stays fixed. The final side length is not the same as the length of the side part that has been cut for pins.

Here's what happened. The half blinds in the 3/4" top and bottom parts dovetailed only 1/2", leaving an exta 1/4" alone. When you assemble the top and bottom to the sides the resulting finished side length is 1/2" longer than the side parts length (1/4" extra at the top and another 1/4" exta at the bottom) due to the half blind tails "extra". That's what happened on the doors.

To make matters worse, I did the exact opposite on the cabinet. That made either the doors too narrow and the cabinet too short or the cabinet too wide and the door too long. Given the function of the cabinet and doors, the doors are right and the cabinet is wrong. Pile a bunch of tools on the bottom of the cabinet the way I built it and the bottom will fall out if the glue fails. The dovetails provide no mechanical connection to the sides of the cabinet.

So this two door cabinet has two screw ups. The orientation of the dovetails is wrong AND the cutting screw up. Do I get double dummy points for this one?