Exploring Internal Lighting Possibilieites

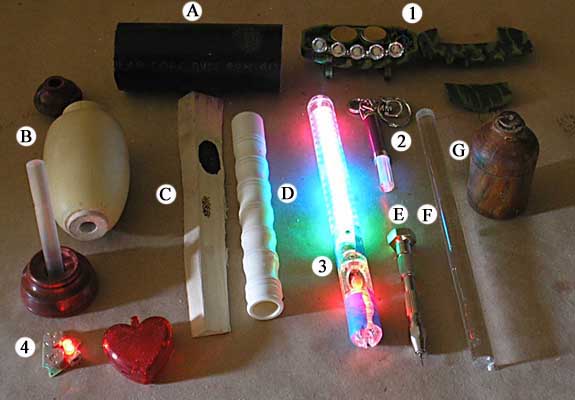

The idea of internally lighting a turned hollow form - lidded box, narrow necked vase, etc. - got me hunting for little battery powered LEDs. They're pretty easy to find because they're being put in EVERYTHING. I got four, none over three bucks. In the photo below (1) is a five LED clip to the visor of your hat, light, (2) is a little LED keychain, (3) an LED light stick I guess to hang around the neck of a kid on Halloween night and (4) a flashing LED heart shaped dog tag thing.

Having an internal light source, I could start playing with transmitted light (through holes in an opaque piece) and translucency (thin walls let some light through while thick walls don't).

I began with piercing, specifically small, really small, holes - at diffrent angles. Had a piece of black ABS pipe (A) which I painted the inside of white for refelctivity, a cordless drill and a set of brad point drill bits. Quickly discovered that "normal sized" drill bits made holes that were too large for this application. I wanted points of light, not big dots of light. I was after holes that wouldn't be obvious holes, but look more like merely a texture. And for angled holes to be only seen when you look right down them - at the internal light - hey had to be pretty small relative to the wall thickness they're drilled through. Quickly discovered that small "normal" drill bit sizes were too big. So off to a hobby shop for some really small drill bits - and something to hold them with - a pin chuck (E).

While the hobby shop tiny twist drill bits produced the holes I was after, both in the ABS pipe, and in wood (C), drilling holes using a pin chuck very quickly became a hand cramping exercise in masochism. I needed a small collet chuck that would fit in a cordless drill - or better yet - a small flex shaft (motor on one end, flexible shaft inside a sleave, and a small handpiece on the other end that would hold the collet chuck. Much easier to control than a larger cordless drill. A trip to a lapidary and jewelry supplies store got me both. AND - two doors down was a TAP Plastic store - that had clear acrylic rods - in 1/8" to 1" diameters. The also had 1/8" diameter fiber optic "cable" for a buck fifty a foot. Bought a foot long 1/2" diameter clear acrylic rod and passed on the fiber optic cable - maybe later.

More holes in the ABS, some more in a scrap of wood (C) and it was time to test the idea on a little lidded box I never finished (G).

Some hole drilling, a little pyrography, some black felt tip pen touch up and a little red flashing LED inside - and I had this. The red light streaming through the little holes was brighter than what shows up in this image. Neeed to tone it down to make it visible, but not irritating, I was after subtle - not IN YOUR FACE!

Now if you shine a light in the bottom of an acrylic rod and shine light in one end - almost all that light will shine out - the other end. The sides of the rod don't let light shining parallel to it out. BUT - if you scuff the outside of the rod - say with fine sandpaper - light can escape from the sides - and the rod will glow softly. Just the look I'm after - see?

So now I can hide the LED light source - and its batteries and switch - say in a pedestal or handle - and get most of its light up into a piece via a scuffed acrylic rod.. The LED Light Stick (#3 in the photo at the top of this page) has LEDs up its length - no need for an acrylic rod to carry light up into something. What if I surrounded the LED Light Stick with something translucent?

Hmmmmm. If I turned a sleeve to fit over it out of wood - and the wall was turned VERY thin - it might be translucent enough to glow. But turning something that long - and that thin would be tricky - and the piece would be extremely delicate and brittle.

Hmmmm. I need a cylinder of something the light stick will fit in - and that is - or can be made - translucent.

Hmmmmmmmmm . . .