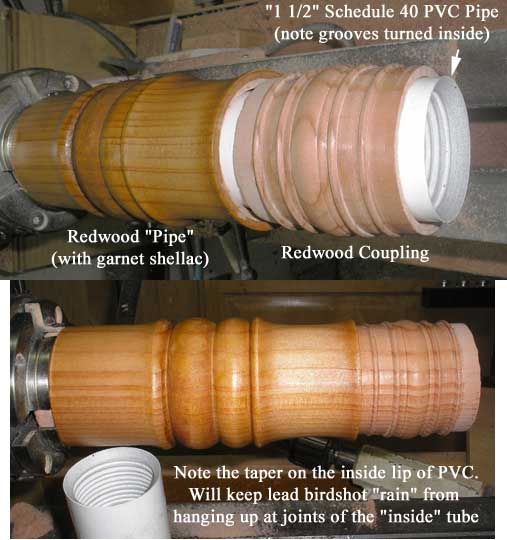

With all of the Inner Tube PVC pipe sections grooved on the inside it was Stock Selection Time for the Outer Tube. Needed something that could start at about 3" diameter and 6 to 7 inches long (about the limits of my JET mini/midi if the piece needs to be hollowed. Conventiently, I had a 14" piece of a nice straight grained redwood 4x4 fence post. Light, easy to turn (if you sand a lot after turning) and nice looking. Also found a "short" about 4" long of the same stuff to experiment on.

A little turning, a little drilling with some forstner bits, a bit of hollowing with a 1/2" skew - and I had an Outer Tube "coupling". More of the same on the first of two 7" long sections of redwood 4x4 and I had this. Notice how closely I'm following The Plan from the previous page - NOT. For some reason, I just can't seem to keep things simple.

Normally, couplings have the pieces to be coupled slip INSIDE the coupling. When I turned what is now a coupling, intending to just try ways of making an Outer Tube for the Inner Tube to fit into I hadn't gotten to how I was going to connect Outer Tube sections. Like most of my projects, unforseen potential problems get solved - before I even know I have a potential problem. And THAT is something I've learned from my Wild Hare Idea projects - decide on a concept - focus on WHAT - and the HOW will become apparent along the way. DO NOT kiss off an idea for a piece just because you don't know how you'll do it or if it requires trying something you haven't done before that you think will be too difficult. When you get to the How In Hell Am I Gonna stuff - by then there'll probably several options waiting for you.

Here's a great example of Things Happen When They Need To Happen.

When you're hollowing - through an inch and a half hole - and the tip of the tool is hanging out 6 or 7 inches beyond the tool rest - it's nice to be able to see where the cutting surface is and how the cut is going. That requires illumination. But even a good gooseneck lamp won't do it - without obstructing your view - which sort of negates the benefit of light.

I'd been picking up all sorts of battery powered LEDs - for some future internally lit pieces - and had one of these in the pile of LED Stuff. Only problem with it is - that you had to keep a finger on the on/off button in order to keep the LED lit. But I figured I'd tape it onto the skew I was using for hollowing - and figure out a way to keep it lit .

Didn't need the clip on the thing for what I had in mind - so I tried to slide the clip off - and discovered that when it was rotated over the on/off button - it pressed down on the button - and turned the LED on. SWEET - an odd way for a switch to work - but still SWEET.. It's light, small and unobtrusive - works - and it's CHEAP. Solutions appear when an unsurmountable obstacle presents itself. And if you abandon an idea because it may involve a potentially unsurmountable barrier - slick solutions, which you can use for other project - remain hidden - with you on the wrong side of the barrier.

Once in a while, you just have to make a leap of faith - and step off - into the unfamiliar. Worst case, that's not going to be fatal. More likely the journey will prompt other journeys - into other unfamiliar - and interesting - territory.