Like so many other woodworking tools, turning gouges and chisels proliferate.

Like other hand tools, they seem to have a self destructive inclination - rolling off the bench - onto the concrete floor below, or banging into each other, often dinging sharp edges or corners. And they hide too - behind something, under a pile of shavings - anywhere they CAN. They''re in some ways like kids - they need bounds or they get into mischief. Like most other tools, they'd like a place they can call home - some place to return to when not playing.

SO - during a visit with Peter Pipe, an expatriated Brit gentleman, I noticed his turning tools holder. Like most good ideas, his solution was obvious - once you saw it - a cube with holes in the top. DUH! Sits on the floor, easy to move around and the gouges are all readily accessible. Perfect! Six pieces of 1/2" ply, some pvc pipe, drill some holes, a little epoxy - DONE! "I'm going to make me one!"

Well, if you've gone through any of my other projects you know I have trouble sticking with K.I.S.S. (Keep It Simple Stupid). The engineer in me wants to Optimize, the Programmer side of me wants to provide Options and Multi-tasking and the artist/craftsman bit wants it to look nice and work well.

Rather than a simple ply cube, why not put a lid on it, add some latches and have it also be a carrying case? Canvas tool rolls really don't work for turning tools - they're long handled and the handles are all different diameters. BUT - in a case with pvc sleeves for them to sit in . . .

Hmmm - why not make it so the tool holder part sits on the upside down "top"? Keeps the parts together and gets the tops of the handles up where you can get them without bending over so far.. Of course all the edges need to be mitered - looks less like ply that way. I've got the lock miter router bit, why not lock miter all the edges? (yes, you can make a closed box with all lock mitered edges - click here for how). Had some 1/2" baltic birch ply that'd be perfect.

Rounder up the tools, did a bunch of measuring and it was off to gets some pvc pipe. Some simplte CAD work and I came up with this.

NOTE: PVC pipe OUTSIDE DIAMETERS DO NOT COME IN FORSTNER BIT SIZES.

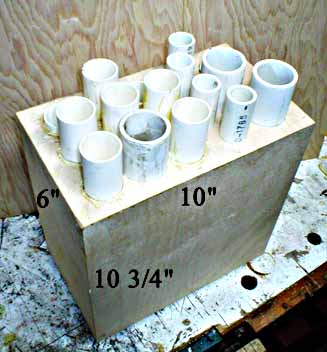

Here's what I've got so far - 13 tools in a 6" x 10" footprint, with room for three more tools. If you leave the pvc "sleeves"long, use them for alignment during glue up and cut them to final length last, then you can custom cut them to get the tops of the handles "stepped". Makes them easier to get to. When you've got them how and where you want them, a little epoxy or gorilla glue on the bottom will keep them there.

It was at this point that this "simple" tool holder got away from me. The baltic birch ply looked too vanilla. Eight or nine coats of garnet shellac took care of that. The "base" needed a "shoulder" for the top to sit on so I added the birds eye maple - ply in this case. But the top endge of the birds eye ply was ugly - so added some claro walnut to the top of the bottom and the bottom of the top. The latches to hold the top onto the bottom will go on the walnut. Looked good. But then the top of the top, which will become the bottom of the tool stand, looked too plane and the garnet finish would get scratched up sitting on the floor. So the top of the top got some walnut to act as legs when this thing is in tool stand mode.

Now "all I need to do is" sand everything down, re-garnet everything but the birds eye maple and install the case latches. Hmmm - wouldn't it look nice with some maple string inlay on all the faces of the baltic birch? And maybe more in the walnut - just for contracst. Oh - and how about a rosette or shell inlay in the middle of the top's front? Better yet, a turned medallion with flutes carved in it!

OR - I could just work out a carrying handle and call it DONE.