"S" is for Spires, Minarets and Spinarets Insprations

Peter Pipe was kind enough to regrind one of my skews to put a curve in the cutting edge. That changed skews from my least used, most"feared" tools to my absolute favorites. The more I use them the more things I discover they can do. I now have four of them - 1/2", 3/4", and seldom used 1" and a 1 1/4". Haven't ground the curve in the 1" yet but will when I have the need to use it.

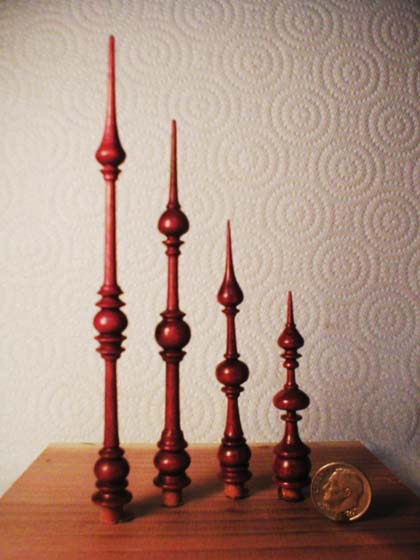

After turning the Ants (see "A" is for .... Ants & Ahnks) with 18 spindly legs and long thin antenae, and working on the thin legs for the Spider, I wondered how fine I could turn a finial. Having played with Santos Mahogany (Brazilian) and becoming familiar with how it turned and took and oil finish, I started playing with it on the lathe - with no real plan other than to do "middle east type spires / minarets". Began with the shortest and progressed to the tallest, getting more delicate as things progressed.

It's funny how the brain rewards creative experimentation - "That's creative - here's some endorphin".So I did another and another, each producing a nice endorphin reward.

The smallest finial took about 45 minutes because there were a lot of pauses for "Now what should I do?" If I had this one to look at, I'm sure I could do a similar one in maybe 20 minutes, 25 minutes tops.

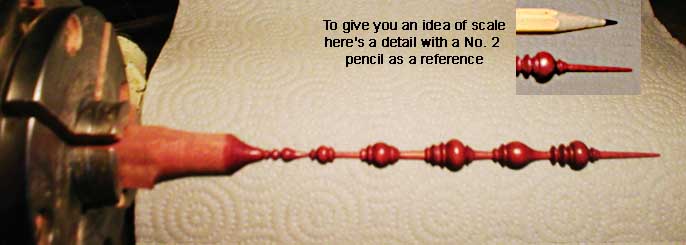

The tallest one took close to an hour and a half to do, again, some of that time was spent on "Now what should I do?" but most of the time was working SLOWLY and very carefully on the long thin tapers. You start at the tip, the piece held at the "bottom" in a chuck and the other end supported by a "live center". Completely finish the top, then work down the next section. Once the "top" is done the piece is held only at the other end, in a four jaw chuck so there’s no “going back”. Turn it and finish it - before moving "down" the blank.

While the piece is being created, you see it "sideways" and while on the lathe, even when you turn your head sideways, you really can't visualize it upright and standing alone until you take it off the lathe. Only then is there an AH! - or an AH SH*T! I shoulda, coulda, woulda . . .

Looks kind of different when seen vertically. I think the one on the shorter one below will make an interesting pendant. Have no idea what the other one is good for, maybe the prototype for a series of very expensive tooth picks for some rich lady's hors d'oeuvres (how the French get "or dew ers" out of that is a mystery to me. I suspect they have words you can spell but can't actually pronounce - ALL the letters being silent - you just move your mouth but don't let any sounds come out.).

It's interesting how the look of these things change as you change their orientation. The long one below seems longer and more delicate when viewed "point down than" when viewed "point up"

ps - One of the tricky cuts used in these pieces is a Roll - Slide - Roll for the top part of the tear drop shapes. The curve on the cutting edge allows a cut that's impossible to do with a straight edged skew chisel because the long point would catch in the transition in the S-Curve and the long point OR heel can easily catch in the long tangent tapering area.

Here's an attempt at animating this cut.

If you're looking for something to turn you might want to have a go at some Spinarets. They really aren't that difficult to do - with a little practice - and a sharp cutting edge.